Marshmallows are sugary confectionery items that are popular throughout the world. They were originally used for medicinal purposes and contained the root of the marshmallow plant, sugar, gum and egg-white. Since those times the basic ingredients have remained unchanged with the exception that marshmallow root is no longer used. Marshmallows are relatively easy to make, but do require a certain amount of food processing knowledge and skill.

Marshmallows are sugary confectionery items that are popular throughout the world. They were originally used for medicinal purposes and contained the root of the marshmallow plant, sugar, gum and egg-white. Since those times the basic ingredients have remained unchanged with the exception that marshmallow root is no longer used. Marshmallows are relatively easy to make, but do require a certain amount of food processing knowledge and skill.

There are various adaptations of the basic recipes to make products that suit individual requirements. This technical brief describes the principles behind making marshmallows and includes two different recipes. You should try out both methods and see which is most popular in your area. Also, try experimenting with adapting the recipe to suite your own market.

When trying out recipes of your own, it is important to remember that the product must be safe to eat over a time period which satisfies the marketing, transporting, storage, retailing and eating characteristics of the product. This is referred to as the shelf-life.

What is a marshmallow?

A marshmallow is a light, fluffy sweet that is made by beating air into a sugar solution that contains a type of gum (eg gelatine), colour and flavour. The mixture is then poured into moulds and allowed to set. To explain some of the science behind the process: beating air into the gelatine solution produces a structure not unlike that of bread, although with smaller air bubbles. The gelatine will eventually harden and will trap the air that has been added to the mixture. The resulting product is spongy and slightly rubbery.

How to make marshmallows

The basic ingredients and approximate proportions are as follows:

Sugar – 40-48%

Glucose – 0-25%

Water – 24-30%

Gelatine- 2-3%

Flavours- minimum

Colours- minimum

The role of the different ingredients in the manufacture of marshmallows

Albumen (egg white). Some recipes include the use of albumen (egg-white). When it is beaten with sugar, egg white can hold a lot of air, which gives the marshmallows a light texture. However, the egg white is not cooked, which is a food poisoning hazard, especially in hot countries. Marshmallows made without egg white taste as good as those made with it, are more stable and less prone to spoilage. It is therefore recommended that small-scale processors use recipes that do not contain egg white.

Cream of tartar and/or citric acid. These two ingredients assist in the inversion of sugar which improves the keeping quality of the product. Inversion is a natural process that happens to sugar when it is mixed with acid such as citric acid or lemon juice (see the box below). The inverted sugar is less likely to form crystals during storage than the non-inverted sugar, which improves the texture and quality of the marshmallow. In addition, cream of tartar gives a mild acid taste to the product which some consumers prefer.

The use of these ingredients may allow the amount of glucose, added in its pure form, to be reduced because the inversion process increases the overall amount of glucose in the recipe (see the box on invert sugar).

Glucose is a hygroscopic substance ie it attracts moisture. Therefore, it is important to use the minimum quantity of glucose necessary to prevent crystallisation of the sucrose. This will minimise the tendency for the glucose to attract water and increase the storage life of the marshmallows.

* A note on invert sugar

The normal sugar that you buy in the shops has the chemical name of sucrose and is composed of two different sugars: one unit of glucose joined to one unit of fructose. The inversion of sugar is the chemical breaking of the link between the glucose and fructose units which results in a mixture of: sucrose units, glucose units and fructose units. This mixture is known as invert sugar. (Complete inversion to glucose and fructose has special applications in the food industry).

In certain food processing activities this inversion process is very important. For example in the case of marshmallow the inversion process is necessary to increase the shelf life. It minimises the chance of the sucrose going back to its crystalline form which is unsatisfactory for good quality marshmallows.

If you cannot obtain glucose, you can use sugar (sucrose) to make marshmallows. You need to add cream of tartar to invert the sugar. Dissolve the sugar in the water with the cream of tartar and boil until it reaches 116°C. Then use the liquid invert sugar as per the marshmallow recipe. This method cannot guarantee the amount of glucose produced during the inversion. Therefore, once an acceptable procedure has been found, the conditions of processing should be adhered to.

It is the responsibility of the producer to try out different methods to find the most popular and optimum mix of ingredients to suit the local market. This should take into account consumer taste and preference, the availability of appropriate packaging materials and the local climate (marshmallows will have a shorter shelf life in humid environments).

Essences and colours

These ingredients are used to give the marshmallows a satisfactory appearance and taste. They are available in powdered or liquid form. Powdered flavours or colours should be mixed with the gelatine prior to adding it to the very hot water. Liquid flavours or colours can be added during beating. It is most important to only use food grade quality essences and colours. If these are not available in your local shops you could try at a local bakery.

The most commonly used essences are rose water and vanilla, but you can experiment with any essence you want to.

Any food grade colour could be experimented with according to local preferences and local regulations.

Processing quality assurance

Marshmallows contain a high proportion of water which increases the likelihood of spoilage during storage. To minimise the risks, it is important to use the correct amount of water in the recipe. You should ensure that all water used is boiled and safe to drink and the ingredients used must be in a good condition. Marshmallows are not cooked during processing or before consumption. Therefore strict attention should be paid to cleanliness and hygiene of the processors, equipment and the processing room,

Packaging is very important with regard to the safety, quality and shelf-life of the product. Marshmallows readily attract moisture and quickly become spoilt, especially in a humid environment. Polythene will form a good barrier against dirt and insect contamination, but does not keep out the moisture. Polypropylene and cellophane are the recommended packaging materials for marshmallows produced in tropical climates.

Typical method for making marshmallows at small-scale

Most of the equipment used for making marshmallows at small-scale is normal domestic equipment that is likely to be found in most households. However, there are some items of equipment for which special purchases may have to be made:

Electric whisk

Confectionery thermometer

Moulds

Packing materials

Essences and colours

Very large icing bag and nozzle

Electric or gas hotplate

Saucepans (preferably aluminium or stainless steel)

Measuring scales (0‑100g and 0‑1kg)

Wooden spoons

Electric whisk

Marshmallows need to have air beaten into them – the more air, the lighter the product and the larger the volume of the final product (you make more marshmallows for the same amount of ingredients, which increases the profitability of the process). Although this can be done using a hand whisk it is time-consuming, hard work and the quality of the product is often low. Furthermore, improved beating results in a drier product because the water particles are better dispersed on the inner surfaces of the marshmallow structure. For these reasons, an electric whisk is recommended.

Confectionery thermometer

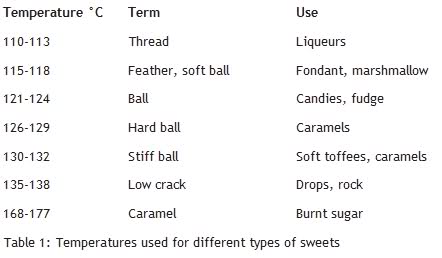

In the manufacture of sugar-based sweets the temperature used for processing is very important and has an impact on the quality of the final product. Generally speaking, the higher the temperature the harder the final product (see table 1). A confectionery or sugar thermometer is a useful piece of equipment because it has the different temperature categories clearly marked. If one is not available, you need to use a thermometer with a very clear scale marked on it. For marshmallows, the temperature of the sugar solution should be raised to 116°C.

Moulds

Moulds are needed to give the marshmallow sweets a shape and form. There are two basic options – the first is the easiest but can result in fairly unimaginative marshmallows. It involves pouring the beaten marshmallow mixture into a tray that has been lightly covered with butter or margarine and lightly dusted with a mixture of cornstarch and powdered sugar. The dimensions of the tray relate to the amount of mixture and the final size of the marshmallow pieces desired. When the marshmallow mixture has set, it is turned out of the tray and cut into cubes using a blade or scissors. The pieces are then dusted with a mixture of cornstarch and powdered sugar.

The second option is known as a starch mould. The mould is formed by preparing a tray of cornstarch – not packing it too tightly. Impressions are made in the starch using shapes. Commonly the moulds are made from wood and more adventurous marshmallow producers have even made animal shaped moulds. The mixture is boiled and poured into the impressions in the starch. Once the technique is perfected many interesting marshmallow shapes can be made. Using starch moulding the marshmallow pieces set much more quickly and the starch has a drying effect which prolongs the shelf-life.

Two tried and tested marshmallow recipes

Recipe A

600g sugar

400g glucose

250ml water

50g gelatine

250ml very hot water

5g citric acid or 1tbs lemon juice

Flavourings or colourings

Method

1. Dissolve the gelatine by adding it to very hot water and transfer to a mixing bowl. If you are using powdered colour and flavours, add these, together with the citric acid, to the gelatine.

2. Boil the sugar and glucose, with at least 250ml of water, to 116°C. The quantity of water is not critical provided that the minimum has been added. More water will result in a longer time to reach 116°C. Using more water is useful for recipe B (with cream of tartar added) because the longer heating time will cause more inversion of the sugar.

3. Slowly pour the hot sugar solution in a thin stream into the gelatine solution, beating all the time. Continue to beat until the maximum volume is attained (approximately 5-10 minutes). If you are using liquid colours and flavours, add them at this point.

4. Pour the mixture into the prepared moulds. Leave to set for 30-60 minutes.

# If using the starch moulding technique transfer the bowl containing the mixture to a boiling water bath and heat sufficiently to allow the batch to be poured into the starch mould. A large icing bag is very useful for piping the marshmallow into the moulds.

# If using the oiled and floured tray technique it might not be necessary to include the additional heating stage. Pour the mixture into the prepared tray.

5. Dust the pieces in a mixture of powdered sugar and cornflour.

6. Pack in moisture proof packaging (polypropylene or cellophane).

Recipe B

1000g Sugar

10g Cream of tartar

500ml (250ml for Gelatine, 250ml (minimum) for sugar) Water

50g Gelatine

5g Citric acid (or lemon juice)

The minimum Colourings/flavourings

Notes on method

Follow the same procedure as for recipe A. Recipe B is significantly cheaper than recipe A but the marshmallows may have a shorter shelf life.

It is evident from these two recipes that there is no single recipe for making very good quality marshmallows. Different climates, different equipment and different qualities of raw materials in different countries are some of the reasons for this. The basic method needs to be adapted to suit your local conditions. Having a good knowledge of the scientific principles behind the method is essential if you are to successfully adapt the recipe. As a small-scale entrepreneur, you should experiment with different combinations of ingredients to make the best (and most profitable) product for your particular conditions. You will need to continually strive to improve the product to remain competitive. Most of this will come through increased familiarisation with the ingredients and process over time. If you follow the principles of good manufacturing practice, you should make deliberate small changes to the recipe and record the changes and the effect on quality of the final product. This will help with the development of a high quality product that meets the needs of your consumers.

Practical Action

The Schumacher Centre for Technology and Development

Bourton-on-Dunsmore

Rugby, Warwickshire, CV23 9QZ

United Kingdom

Tel: +44 (0)1926 634400

Fax: +44 (0)1926 634401

E-mail: inforserv@practicalaction.org.uk

Website: http://www.practicalaction.org

This document was produced by Dr. S Azam Ali for Practical Action in March 2008. Dr. S Azam-Ali is a consultant in food processing and nutrition with over 15 years experience of working with small-scale processors in developing countries.

Do you like this Money Making Business Idea? content“> then please consider subscribing to our Pinoy Bisnes RSS feed. You can also subscribe by email and have new articles sent directly to your inbox. (Once you entered your e-mail address, you need to login to your e-mail account and click the link to confirm your subscription).

very good i wil tray