The process of making charcoal briquettes from agricultural waste is not new. Many institutions have experimented on different agricultural residues to find out which raw materials are possible for charcoal making. They encourage the use of dry organic material (also called biomass) that is unsuitable for animal or human consumption, or for composting such as sugar cane bagasse, palm leaves or bamboo, coconut shells and husks, straw and reeds, corn cobs and other farm crop wastes.

Agricultural residues from harvested crops, using biomass charcoal briquetting techniques, can be converted from piles of waste into useful and enviro-friendly briquettes. It can be sold to generate additional income for the family.

How to Make Charcoal Briquettes?

Below is the process from India Development Gateway – Biomass Charcoal Briquetting. Use this method on how to make charcoal briquettes, and produce your own homemade ones.

Methodology

There are two different methods of charcoal making.

1. Direct method – The direct method is to heat and form an incomplete combustion of the organic matter that results in the formation of charcoal.

2. Indirect method – In the indirect method an external heat source is used to “burn” organic matter kept in a closed but vented airless chamber. The indirect method results in production of high quality charcoal with less smoke and pollutants.

MCRC’s method of charcoal briquetting

Requirements

1. Locally available biomass (eg casuarina leaf litter, sugarcane trash, rice husk, coir pith, groundnut shells, etc)

2. Carbonizing chamber (furnace )

3. Binder (starch or cassava flour)

4. Mini Briquetting machine (10kg/hr)

Stepwise process of charcoal making

1.Collection of biomass

Collect the locally available biomass, sort them, chop the large-size raw materials into smaller pieces and dry at sunlight.

2. Carbonization

i. Designing the Furnace

i. Designing the Furnace

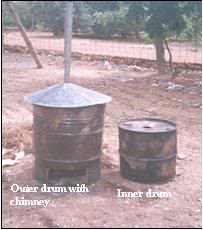

• Outer drum : A 200lits. metal oil drum with the top cut out and a 12″ width x 10″ height hole cut in the lower side

• Two iron rids (8”) has to be fixed at the bottom of the metal drum running parallel from one side to the other side. This iron rods act as base to support the stainless steel inner drum.

• Inner drum : A 100lits stainless steel drum with proper lids and six (3/8″) holes at the bottom.

• The inner drum is placed into the larger drum.

ii. Carbonizing the biomass

• The biomass is tightly packed into the inner drum and fired for 45minutes to 1hr (Depending upon the biomass) using biomass.

• After firing, the carbonized biomass in the inner drum has to collected and weighed. In this method 30 % of carbonized char can be obtained.

3. Preparation of binder

The binder material is used for strengthening the briquettes. For every 100 kg of total weight of carbonized charcoal powder, prepare a binder mixture by adding 5 to 6 kg of starch or cassava flour to 60 – 100 litres of water (based on the weight of the raw materials) -(For example: 80 liters of water to be mixed with 5 kg of starch powder then boiled till stickiness is formed and added to the 100kgs of charcoal dust. )

4. Mixing

Mix such that every particle of carbonised charcoal material is coated with binder. It will enhance charcoal adhesion and produce identical briquettes.

5. Briquetting. The charcoal mixture is made into briquettes either manually or using machines. Pour the mixture directly into the briquetting mould / machine to form uniform-sized briquettes.

6. Drying and Packaging

Collect the briquettes in a tray, dry them under the sunlight, pack them in plastic bags and seal

General Characteristics of briquettes

Moisture : 7.1%-7.8%

Volatile Matter : 13.0%-13.5%

Fixed Carbon : 81.0%-83.0%

Ash : 3.7%-7.7%

Sulfur : 0.0%

Heating Value : 7,100-7,300 kcal/kg

Density : 970kg/m3

Advantages of the technology

1. Smokeless: The charcoal briquettes burn without any smoke during ignition and burning.

2. Low Ash content: Minimum residual ash is formed (less than 5% of the original weight of the charcoal).

3. Higher Fixed Carbon & calorific value: Normally the concentration of fixed carbon will be about 82%. The calorific value of charcoal briquettes is 7500 Kcal/KG.

4. Odourless: The biomass charcoal briquette contains minimum evaporative substances, thus eliminating the possibility of odour.

5. Longer burning hours: Two times longer burning hours compared to hardwood charcoal.

6. Sparkless: These charcoal briquettes will not produce sparks as compared to hardwood charcoal.

7. Less crack & better strength: Less crack & better strength make the charcoal burn for a long time.

For further details please contact

Director

Shri AMM Murugappa Chettiar Research Centre

Taramani

Chennai 600 113

Tamilnadu, India.

Phone: 044-22430937

Fax 044-22434268

E.Mail : energy@mcrc.murugappa.org

Sources: indg.in, fao.org, enotes.com, practicalaction.org, mitadmissions.org

Beston Group supplies charcoal kiln and complete service (customized solution, production and delivery, installation).

I do believe all the ideas you have introduced for your post

I have tried using carbonized rice husk prepared manually by myself to make bbq,charcoal in round shape,unfortunately I could see no flame on burning them .Where did I go wrong? Please, I need your advice

Thanks for guiding me on how to make charcoal from Rice Husk Ashes

San nkkbili dito ng machine for briquetting? Sa pinas.

we sell coconut charcoal briquettes and briquettes machine pls contact 09972871286

Da ideas are very good. Thank u

I’m a second year university student I have abusiness idea if you can take this opportunity to be an investor in both crop residues and animal waste management to produce fuel of carbonized charcoal, organic fertilizer, adsorptive and timber products ie chip boards from corn cob. I have good connection wwith our county government for your investment. My contacts are 254 726 85 82 35/ 254 787 280 096.All crop residues are not put into any use and they are about ten million metric tones and over. Please for more information contact me as we plan to look forward to work together and improve the livelihood of the community.

ask ko po kung saan makabili sa filipinas ng mini charcoal briquettes machine? thank you..

Unfortunately there's no market for charcoal briquettes in the Philipppines. Majority of Filipinos will not use briquettes even if the price is lower than the lump charcoal that they commonly use. Charcoal briquettes though is much indemand abroad.

meron po ba kayong data ng heating value ng cassava starch?

ask ko lang san ako pwede makakuha ng makinang pang briquette, eto no. ko 09064316752

where can we buy charcoal here in manila

charcoal peddlers are everywhere in Manila. but you easily find charcoal at all public markets

this is really very informative. keep on…

ask lang po kung gaano karaming gawgaw ang kailangan sa 100 kilo na biomass at saan nkakabili ng hulmahan ng briquette tnx

As per instruction don sa procedure, here it is: For every 100 kg of total weight of carbonized charcoal powder, prepare a

binder mixture by adding 5 to 6 kg of starch or cassava flour to 60 –

100 litres of water (based on the weight of the raw materials) -(For

example: 80 liters of water to be mixed with 5 kg of starch powder then

boiled till stickiness is formed and added to the 100kgs of charcoal

dust. )

san nakakabili ng briqueting machine?