Why MANGROVE CRAB?

Mangrove crabs (Scylla spp.) or mud crabs, locally known as “alimango,” inhabit muddy and sandy bottom in brackishwater and marine environments. They dig deep burrows in mangroves and soft substrates in shallow or intertidal waters. Widespread interest in Scylla species is increasing due to their demand both locally and internationally. Northern Mindanao, Central Luzon, Western Visayas and Bicol Region are the top producers of mangrove crabs in the Philippines.

How to culture MANGROVE CRAB?

Hatchery

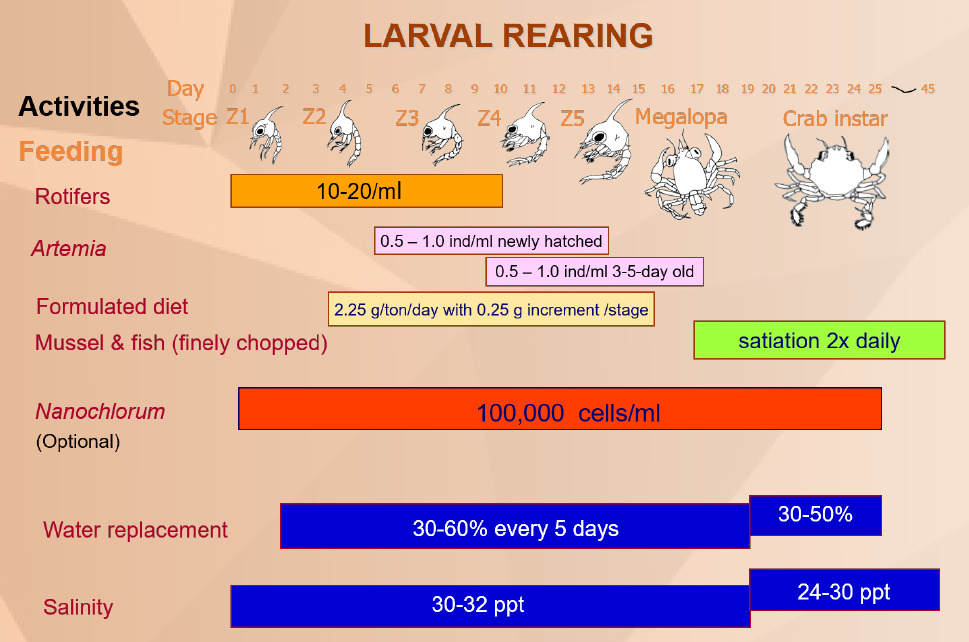

Healthy mature female crabs with complete limbs are chosen as broodstock. The crabs are maintained in the tank with sand substrate until they spawn. After hatching of eggs, the zoeae (larvae) are stocked in tanks at 60-80 individuals per liter. Figure 1 shows the feeding and water management schemes for mangrove crab larvae. Megalopae or crab instar (crablets) are transferred in tanks or net cages and cultured for 3-4 weeks. These are fed minced fish and mussel meat alternately.

Figure 1. Feeding and water management in larval rearing (Quinitio, Parado-Estepa, and dela Cruz-Huervana; 2018)

Suitable ranges of water quality for mangrove crab larvae

| Temperature | 27-30°C |

| Salinity | 28-32 ppt |

| Dissolved oxygen | ≥ 5 ppm |

| pH | 7.5-8.5 |

| Unionized ammonia | ≤ 1 ppm |

| Nitrite | ≤ 0.1 ppm |

Procedure

- Obtain healthy adult crabs 500-700 g for S. serrata and 320-500 g for S. tranquebarica and S. olivacea with orange ovaries (‘aligi’) and complete legs as source of broodstock from ponds or traders.

- Put crabs in an empty basin and pour seawater over them slowly. Transfer crabs to basin containing 150 ppm formalin for 30 minutes to disinfect. Transfer crabs in tanks provided with sand substrate.

- Feed crabs with mussel, fish and/or marine worms at 10-15% of crab biomass daily. Change the water 3-4 times a week. Sampling for berried females (females with spawned eggs attached to the flap. Crabs spawn within 2-4 weeks depending on the stage of ovarian maturity when obtained.

- Retrieve berried crabs and disinfect in formalin. Stock each crab in a 500-liter tank with aerated seawater. Feed crabs but discontinue feeding when eggs become brown.

- Siphon out detached eggs and excess food before water change. Change about 80% of the total water volume in the tank daily. Retain 20% of water in the tank to prevent egg desiccation.

- Check for hatching and remove the crabs after all the eggs are shed. Turn off aeration in the hatching tank. Allow dead zoeae, unhatched eggs, feces and other wastes to settle. Siphon them out.

- Cover the tank and siphon zoeae that concentrate in the lighted area with 2-cm diameter hose. Transfer in a bucket with aerated seawater. Estimate the total number of zoeae.

- Stock about 80 zoeae/li in tanks. Feed with rotifers at 10-15 ind/ml until zoea 4 or 5 and newly hatched Artemia at 0.5- 1 ind/ml from late zoea 3 to early megalopa. Feed later stage of megalopa with larger Artemia and/or minced fish or mussel meat.

- Change 30-50% of the water volume every 5 days until harvest. Harvest crab instar (crablets) and stock in net cages.

pond at Dumangas Brackishwater Station

Nursery site selection

A brackishwater earthen pond for fish or shrimp farming can be used for mangrove crab nursery. The site must:

- Have clay or clay-loam soil to easily retain water

- Have adequate supply of clean brackishwater or seawater

- Be protected from flood and siltation

- Be near the roads, source of crablets, traders and market

- Have electric power

Nursery

Nursery is the intermediate phase between the hatchery and grow-out phases. Crablets from the hatchery are reared to the desired size for grow-out phase. Crablets measuring 0.5-0.6 cm carapace width (CW) are grown to 1.5-2.0 cm in net cages or hapas that are installed in ponds (Phase 1). Since some farmers prefer bigger crabs, the crablets from Phase 1 nursery are harvested, sorted and further cultured until they reach 2.5-4.0 cm CW (Phase 2) in net cages or ponds with fence. The ponds with net cages are enclosed with net fence to avoid entry of other species of crabs which may damage the net cages. To minimize cannibalism, the cages are provided with net shelters that serve as hiding place for newly-molted crabs. Feeding consists of chopped mussel meat, low value fish, snail meat, or chicken entrails at satiation or 100% of total weight of stocked crablets per day. If formulated feed is available, a combination of 30% wet feeds plus 70% formulated feed will be a better alternative. Stocking density is 30-50/m2 in Phase 1 and 5-10/m2 in Phase 2. Crablets can be harvested after 3-4 weeks in each phase.

Procedure

Phase 1

- Install net cages after pond preparation and before water is admitted into the pond. If net pens will be used instead of cages, install this prior to pond preparation. Admit water after pond preparation.

- Add ribbon-like nets, bundled short straw (used as tying material) or dried twigs as shelters.

- Stock crablets (0.6-1.0 cm) at 20-50 ind/m2.

- Feed crablets with minced low value fish, molluscs (meat of snails, clams, etc) and/or boiled chicken trash at satiation or 100-150% of total body weight per day. Divide the ration daily and feed to two feedings.

- Change about 30% of water every spring tide or when needed and maintain water depth of at least 80 cm.

- Harvest and sort crablets.

Phase 2

- Install net around the pond perimeter or dike at an angle of 45º before or after pond preparation.

- Stock the crablets (1.5-2.0 cm) at 5-10 ind/m2.

- Feed crablets with fish, molluscs (snails, small bivalves, etc), animal entrails and boiled corn at 50-80% of total body weight/day.

- Follow 5 and 6 in Phase 1.

Packing and transport

Crablets smaller than 2.0 cm CW are transported in oxygenated plastic bags with cool water (24°C). Crablets of more than 2.0 cm CW are transported in boxes with wet cloth or sand. Crabs are better transported early in the morning, late afternoon or during cool weather.

Grow-out culture in ponds

Crabs are commonly cultured with fish in earthen brackishwater pond. Cannibalism in crabs is reduced by lowering the stocking density and maximizing the space by stocking fish. Common combination of crab is milkfish. Crabs (15 g to 30 g) are stocked in the pond with fish and grown for 3 to 5 months. The culture period depends on the initial size of crabs and fish and the stocking density. Two or more crops may be done in a year, depending on the desired crab size at harvest.

Procedure

- Prepare pond using standard procedure. Grow natural food such as ‘lablab’, plankton and other natural food prior to stocking.

- Stock milkfish fingerlings at 2,000-3,000/ha and crab juveniles at 500-800/ha.

- Acclimate animals to pond water before stocking.

- Feed crabs with low value fish, mollusks (snails, small bivalves, etc), animal entrails and/or corn (boiled) once or twice daily. Give an initial feeding rate of 10% of total crab biomass, reduce to 7-8% and then 3-5% daily as the crabs grow older. Use the formula:

Amount of feeds to be given = average body weight x total number of animals x % feeding rate - Put chicken manure inside perforated bags set at equal distances within the pond to maintain growth of ‘lablab’ and other natural food for milkfish.

- Change about 30% of water every spring tide (new moon and full moon) or during high tide whenever necessary. Maintain water depth of at least 80 cm.

- Monitor the condition of the crabs and water in the pond regularly and undertake the necessary remedial measures.

- Select and harvest market size crabs. Selective harvest reduces competition for food and space, and cannibalism.

- Harvest the crabs by using lift nets with baits early in the morning. Crabs can also be collected by scooping while they congregate near the pond gate as water is allowed to enter during water change.

- Harvest totally when crabs and milkfish have reached market size.

- Tie and wash the crabs to remove the mud. Put milkfish in ice.

Grow-out culture in pens

Mud crabs can be grown in pens installed in existing mangroves for up to 3 months. The pen can be rectangular, square or irregular shape and the size ranges from 500-1,000 m2. The use of net enclosures in mangroves offers an alternative to pond culture. It also promotes a better image for brackishwater aquaculture that had been linked to the historical clear-cutting of mangroves to make way to ponds.

Lean crabs may also be fattened using pens set in mangroves within 30-45 days. Mud crab pen culture is recommended in sites with mature mangrove trees in lower part of the intertidal zone.

Procedure

- Enclose the selected area with bamboo slats or nets (durable enough that cannot be destroyed by crabs) with bamboo pole or wood support that are buried at least 50 cm in the soil. Consider an effective height of 2.0-2.5 m or higher than the highest tide in the site. Put an overhang of about 30 cm on top end of the fence.

- Allot about 20% of the total pen area for canals (0.5 m deep) to hold water during low tide. Dig canals in the middle, away from the bamboo partitions to prevent the crabs from escaping to the outside through deep burrows.

- Stock 200-300 g S. serrata or 100-150 g for S. olivacea and S. tranquebarica and grow them in 2-3 months. For fattening, stock lean crabs bigger than the above and fatten within 30-45 days. Stocking can be done in 3-4 consecutive days if quantity is not enough for stocking in one day.

- Feed crabs with fish and molluscs (snails, small bivalves, etc), animal entrails and/or corn (boiled) once or twice daily. Chop animal entrails or fish to the size appropriate to the mouth size of crab.

- Maintain good water exchange by ensuring that water flows in and out of the pen during each tide.

- Inspect canals. A depth of at least 0.5 m should be maintained to permit water to accumulate during low tide.

- Select and harvest market size crabs

- Harvest all crabs when they have reached market size. Tie and rinse crabs. Keep crabs in cool place.

Is MANGROVE CRAB AQUACULTURE profitable?

Mangrove crab is considered a good product choice due to its high commercial value. The price of crablets varies according to their size. Bigger crablets sell at a higher price. Nursery is one form of product development that adds value to the smallest crabs sold to farmers.

Technical assumptions

| Total larval rearing capacity (tons) | 80 |

| Broodstock | |

| % broodstock that will survive and spawn | 45 |

| Average zoeae/female | 1,200,000 |

| Average body weight of broodstock (g) | 600 |

| No. of successful spawners needed | 5 |

| No. of broodstock to be purchased | 12 |

| Kg of broodstock to be purchased (kg) | 7 |

| % of body weight used as basis of feeding (%) | 5 |

| Hatchery | |

| Stocking density of larvae/liter | 80 |

| Total no. of zoea to be stocked at maximum capacity | 6,400,000 |

| % survival from zoea to C1 C2 (crab instars) | 3 |

| No. of crab instar produced/run | 192,000 |

| Number of runs/year | 6 |

| Selling price of C1 C2 (per piece, PhP) | 3.50 |

Costs-and-returns (as of 2016)

| Sales of crablets | |

| Quantity | 192,000 |

| Unit Cost (PhP) | 3.50 |

| Value (PhP) | 672,000 |

| Total Variable Cost | 118,373 |

| Total Fixed Cost | 136,250 |

| Net Income/run | 417,377 |

| Net Income/year | 2,504,262.50 |

| ROI | 42.01 |

| Payback | 2.01 |

Reference:

SEAFDEC Aquaculture Department. (2016). Mangrove crab hatchery and nursery operations [Brochure]. Tigbauan, Iloilo, Philippines: Author.

Recent Comments